Dynamic processes put to the test

Highest flexibility with EBSILON®Professional

EBSILON®Professional, the flexible tool for the planning, design, and simulation of thermodynamic cycle processes, is one of the most advanced software systems you can obtain in the field of plant and power plant technology.

A toolkit for deriving the plant behavior

As a result of the increasing, prioritized feed of renewable energies into the power grid today, power plants have to be able to start up / shut down and change the load respectively faster and more frequently in order to stabilize the power frequency. This happens on the basis of corresponding flexibilization measures. As a consequence of these, however, the operating hours under steady load operation decrease while wear, material stress, and maintenance costs are rising. The service life is thus reduced. So how can you as a project developer, designer, and operator be sure to meet the requirements of a changing market while remaining competitive as early as at the planning stage?

The solution is: with innovative concepts

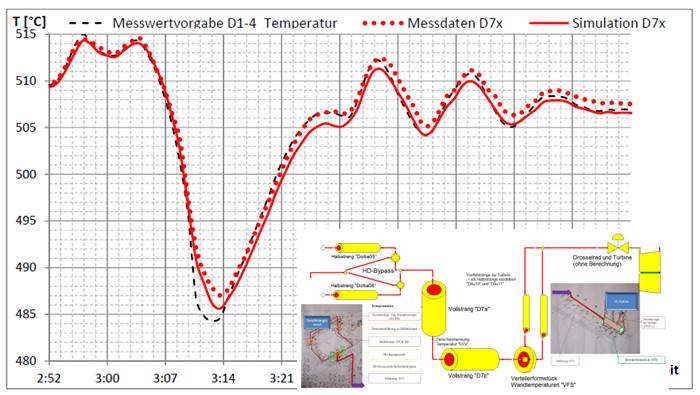

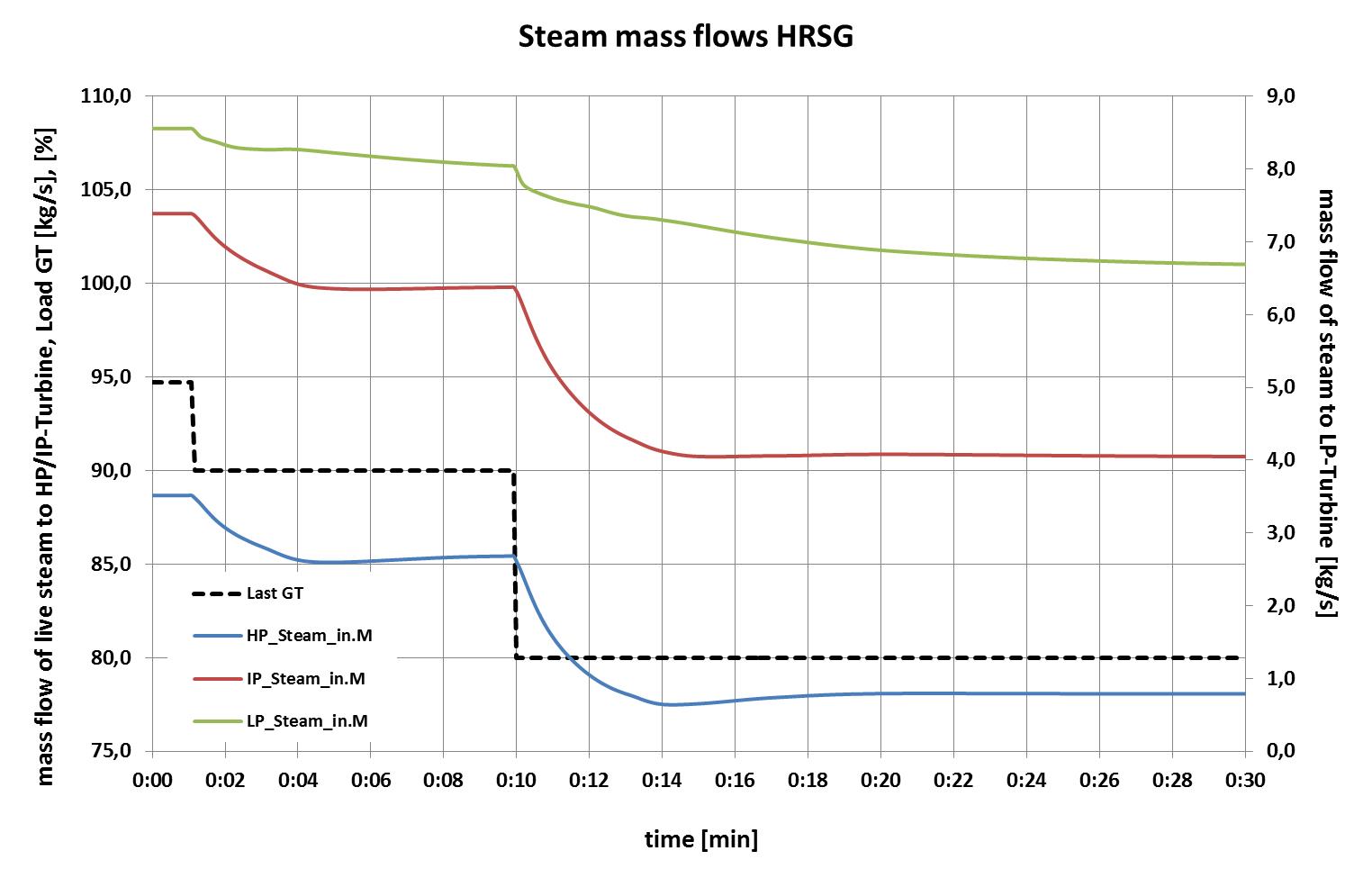

EBSILON®Professional simulates the power plant process including the closed-loop control and derives the dynamic behavior of the plant from the physical properties. To do so, a number of components is available: Various storages, transient heat exchanger, transient piping, PID controller, steam drum, feed water tank / deaerator, steam turbine condenser, feed water heater and ECO / Evaporator / Superheater.

An example:

in the off-design case, the thermal and hydraulic conditions in the heat exchanger change, which leads to a different transfer function (time behavior). E.g. by means of the component “Transient heat exchanger”, the influence of the type of flow and the real structure on the heat transfer is considered. Depending on the depth of the desired representation and the extent of the available specified data like e.g. measured values respectively, the software offers different possible levels of detail of the representation – either geometry-based, using exactly defined component properties, or simplified via the time behavior of thecomponents. Multiple conventional power plant components can be used in both steady state and transient simulations. The existing steady state models can be thus directly used for transient computations.

Iqony engineers have developed EBSILON®Professional from practice

The software offers a crucial additional benefit: often, there are models of steady state design.The transient components allow to convert them cost-effectively and in a short time to enable them to implement the dynamic simulation.

Dynamic components in EBSILON®Professional

- Direct storage: represents the charging and discharging process of a tank.

- Indirect storage: calculates the transient heat exchange of the material with the fluid flowing through and around it respectively.

- Transient heat exchanger: is based on the component ‘Indirect storage’. A second fluid and a second wall are implemented.

- Dynamic piping: offers a fast and easy-to-calculate analytic transfer function, which is determined by the properties of material, liquid, and heat transfer without further input by the user.

- PID controller: compensates a control deviation in transient processes.

- Transient separator with transfer function: Transient processes are represented by means of one or several coupled transfer functions without the need to calculate a detailed physical model.

- Stratified storage: describes a tank filled with a fluid which, depending on the start and boundary conditions, may have a thermal thermocline.

- Storage for compressible fluids: being able to model various gas storages, Compressed Air Energy Storage – CAES, Ruths storage

- Battery: for modeling electric batteries consisting of individual cells

- Thermal regenerator / bulk material storage: various sensible storages filled with bulk / packing materials, thermal regenerators (e.g. Cowper)

- Phase Change Material (PCM) storage: storing heat utilizing the fusion enthalpy at phase transition